LiquidWood®

Structural Epoxy Wood Hardener and Consolidant for Deteriorated Wood.

Uses: LiquidWood® penetrates wood fibers and structurally hardens decayed and weathered wood permanently. Use indoors and outdoors and on both structural and decorative wood. Use to harden and restore wood on buildings, windows, columns, beams, decks, boats, furniture, artwork, and any wooden architectural elements. Use also as a primer or thinner for WoodEpox®.

Features & Benefits: LiquidWood epoxy wood consolidant is easy to use and produces permanent results. Its low viscosity allows it to penetrate deep into the wood and saturate deteriorated wood fibers prior to hardening. This eliminates the need to remove the areas that can be effectively consolidated. With LiquidWood, deteriorated wood that could crumble under finger pressure can be restored to structural, high-strength, durable, weather and insect-resistant wood. The absence of water and solvents eliminates shrinkage and enhances adhesion. It is low odor and produces virtually zero VOCs, making it safe and hazard-free in any environment. Treated wood will harden within hours, and like new wood, can easily be sawed, planed, drilled, nailed, painted, routed, and sanded.

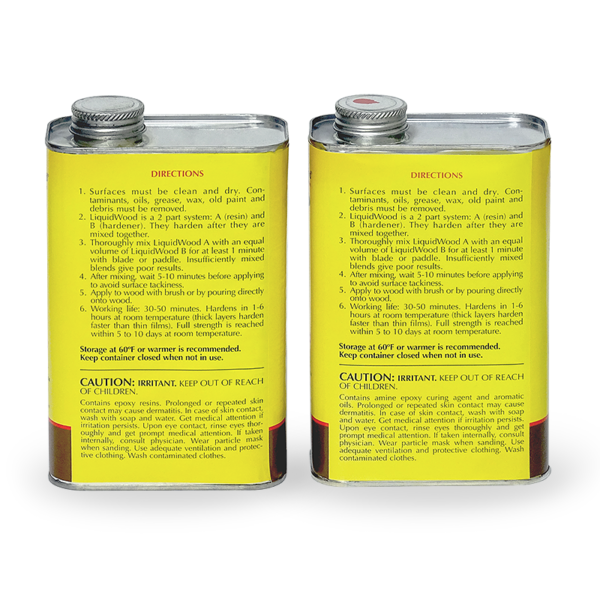

Technical Characteristics: 1:1 mixing ratio. Combine equal parts A and B until fully blended. Pot life: approximately 30 minutes. Hardens within hours depending on temperature and other environmental factors. 100% epoxy solids. Waterproof. Coverage: 231 cubic inches per gallon. Effective coverage varies based on the porosity of the wood. Translucent amber color liquid resin. Apply by brushing, pouring, or injecting directly onto dry, bare wood. Application temperature range: 50-90° F. 100% compatible with WoodEpox.

Cold weather formulation is available for application temperatures as low as 35° F.

This product is GREENGUARD® Certified, meaning that it has been 3rd party verified to contain virtually no VOC’s (volatile organic compounds).

This product is GREENGUARD® Certified, meaning that it has been 3rd party verified to contain virtually no VOC’s (volatile organic compounds).

TYPICAL TEST RESULTS

| Kg/cm2 | Mpa | Psi | ||

| Compressive Strength | 366 | 36 | 5210 | |

| Elongation | 84% | |||

| Flexural Strength | 63 | 6.2 | 900 | |

| Hardness, Shore D | 42 | |||

| Tensile Strength | 103 | 10.1 | 1460 |

Wood Restoration with LiquidWood and WoodEpox

Learn the Basics - Mixing LiquidWood

Customer Questions & Answers

-

I have 10 Aluminum clad Pella doors in a bayfront home. Underneath the aluminum cladding, the wood is soft and rotting near the bottom of the doors. I am considering drilling holes through the aluminum cladding every 3 or 4 inches and injecting LiguidWood into the wood. Does this sound practical and do you have any suggestions?

-

Q I have 10 Aluminum clad Pella doors in a bayfront home. Underneath the aluminum cladding, the woo...... Read more answer nowAsked by on April 6, 2023 8:21 pmAnswered by the admin

You can use the LiquidWood to harden the rotted wood, but you have to make sure the wood contains less than 17% moisture.

Can you apply both the apoxy and liquid wood over an area that has been previously csulked or has plastic wood on it?

-

Q Can you apply both the apoxy and liquid wood over an area that has been previously csulked or has...... Read more answer nowAsked by on March 18, 2023 7:57 amAnswered by the admin

LiquidWood and WoodEpox should be applied to the bare wood so it bonds with the bare wood.

I have a small corner of rotted OSB that is separated in sort of layers. Cannot get to the OSB to remove due to joist. Plan to drill several holes in OSB and inject LiquidWood leaving the outer (exterior or surface) layer dry (no Liquid Wood). Then use a jury rig to press and hold the outer layer squeezing the filled areas. Let interior cure then brush LiquidWood over outer layer, then cure, then use WoodEpox for final thin coat. Is this approach sound?

Also injection will use syringe and stainless steel needle. Can syringe and needle be thoroughly cleaned with Abosolv, or acetone - to be used again? Thanks.

-

Q I have a small corner of rotted OSB that is separated in sort of layers. Cannot get to the OSB to...... Read more answer nowAsked by on March 2, 2023 2:44 pmAnswered by the admin

You can use the LiquidWood to consolidate the rotted wood. It will absorb in and harden up the rotted wood. You can brush it on or inject it. You can clamp the OSB together until the LiquidWood cures to try and consolidate that rotted wood. LiquidWood does no fill a void. You can use the WoodEpox as a thin coat over the LiquidWood. You may have to thin the WoodEpox with the LiquidWood when using as a thing coat. The best time to apply WoodEpox is while the LiquidWood is still tacky. You can clean your tools and accessories with Abosolv or Acetone.

Can this product be applied using a paint sprayer. Specifically looking to to apply it to a large area of 35+ year old cedar clapboard siding. 600 to 800 sf of surface.

-

Q Can this product be applied using a paint sprayer. Specifically looking to to apply it to a large...... Read more answer nowAsked by on February 24, 2023 7:33 amAnswered by the admin

LiquidWood is not really a sprayable product. You would have to thin it significantly to get it thin enough to spray. Also, LiquidWood should only be applied to rotted, soft, spongy wood. It is not to be used as a protective coating or sealant.

Can I use Liquid Wood on a board treated with copper containing wood preservative such as Copper Green or Jasco? I'm using the wood preservative to suppress wood rot fungus in a 2x8 fascia board which I will be covering with aluminum flashing. The board has some deep cracks which I would like to use WoodEpox in. The board is on the west side of the house and gets extreme heat in the Arizona summer.

Thanks.

-

Q Can I use Liquid Wood on a board treated with copper containing wood preservative such as Copper ...... Read more answer nowAsked by on February 20, 2023 11:19 amAnswered by the admin

You can use the LiquidWood to consolidate & harden up any wood and the WoodEpox to fill in any areas as long as the wood is completely dry.

Technical Data Sheet

Technical Data Sheet

j thomas –

Mixing: I use a pair of clear 9oz drinking cups that have horizontal grooves molded in, so it’s easy to get the same level on part A and B. Pour each into a sandwich size ziploc, press out most of the air, and zip shut. Now it’s easy to mix together by kneading the bag. Wait the 10 minutes before using.

It’s usually 4-6 oz of each A and B. I can’t apply much more than this quantity before the epoxy starts thickening on a warm day, so I apply, then make another batch. The same weathered wood often needs this second application anyway.

I use “condiment bottles” from the supermarket (like ketchup bottles). Cut off the corner of the bag, and pour into the bottle, then squeeze out the remainder. This is so easy to apply to a vertical surface with the bottle. As I apply it, I use a disposable “chip brush” to pull the dripping epoxy upwards.

The bottles can be reused if turned upside down to drain completely. The remaining cured epoxy pulls right out of the bottle in one sheet.

Have a large cardboard box or garbage bag lined container. It’s for holding the many paper towels that get used for a session. And the A&B cups, ziploc bags, and used brushes.

Donald Chester –

A hint I might add: After making a small repair using a disposable brush, instead of throwing away the brush, I seal it into an air-tight zip-lock bag and place in the freezer. Even months later, I can take out the brush, let it come to ambient temperature, and it will be perfectly usable. This saves using a new disposable brush each time when I may be applying a small amount every day or two while working on a project, and I don’t end up having to throw away a bag full of hardened disposable brushes.

Donald Chester –

I have used Liquid Wood for years to maintain our 80+ y.o. old buildings. It is the most satisfactory repair product I have yet to try; it does not shrink, and is the only product I have used for both exterior and interior repairs, in which the hardened filler did not eventually separate from surrounding wood, inviting more water ingress and further rot. Repairs I made on wood siding and window sills 20 years ago still appear intact, and hold paint equally well to untreated wood.

I prefer to make my own filler by mixing fine sawdust with Liquid Wood, to WoodEpox. For one reason, after sanding over the repair, it becomes almost indistinguishable from the original wood, other than being a little darker in colour, whereas WoodEpox is stark white making the repair highly visible, particularly on surfaces like varnished flooring and trim.

Although the instructions say not to use it as a sealer, I find that it works well for sealing the ends of sawed pieces, which may wick up moisture and cause soft spots to eventually appear as far as several inches from the end. I use it to seal questionable pieces of old wood, even when I am not sure if it has started to decay. From my experience, if the piece of bare wood soaks up slightly thinned Liquid Wood, it serves a useful purpose. If it does not soak into the wood, it would be a waste of the product to apply it.

One word of caution: be sure to use protective gloves, and clean up per instructions. Otherwise, it may cause a rash similar to poison ivy, and subsequently, increased allergic sensitivity to the uncured product. I discovered that the hard way.

ABATRON –

Thanks for the feedback. We do suggest a longer induction period in order to avoid the tacky-blushing. 5-10 minutes is recommended. Humidity and moisture in the wood can affect the tackiness as well. Using an external heat source can speed up the cure significantly as well.

William H –

The product does what says, but takes a L-O-N-G time fully cure. Both times that I have used it, after 12 hours at ambient temperature (60-80 deg F) the surface is still very tacky. Now, I will say that after I mixed it well a good full minute, I let it sit for the mix to go from foamy to de-air and become clear. Maybe waiting longer would reduce the tackiness, but it took me about 15 minutes to fully apply with a coarse haired brush, so I was confident that the length of time and the constant applying should have given me the required time to not experience tackiness.

Product does what is says as far as binding wood and protecting it. But, if it that time sensitive regarding tackiness, I may look elsewhere for the next time.

ABATRON –

You can thin LiquidWood with Abosolv, Acetone, Xylene or Alcohol.

Er –

I have used it on an old log homes very satisfied with this product I was wondering how to make it thinner so it would penetrate the entire surface and get into the small cracks

Cheri –

I’ve used Abatron products in many areas as we’ve slowly restored our circa 1900 home. It’s easy to use, works perfectly, and has saved us a lot of money and hard work because we’ve restored the original wood parts – rather than replacing them.

Donald Chester –

I have used LiquidWood for years in restoration projects in and around my circa 1865 farmhouse and circa 1930 outbuilding. I prefer to make my own filler by mixing LiquidWood with fine sawdust, since after sanding, the colour comes out close to that of the surrounding wood even before finishing; sometimes it is hard to see where the repair was made, for example, where I repaired a burnt spot in my oak hardwood floor from an errant ember from the wood stove. I have used this method outdoors to repair rotted window sills and siding. It doesn’t shrink and after more than a decade, no cracks have appeared between filler and sound wood. Filled spots take paint just like original wood.

ABATRON –

It’s hard to say how much LiquidWood will absorb into the rotted wood because we don’t know the extent of the rot. You should keep brushing it on and/or injecting it until the product pools on the top, then you know you’ve applied enough product.

Ed –

what is the ration of liquid wood to the beam one would be working with?

ABATRON –

Yes, you can drill holes and inject the LiquidWood.

Chiya –

I have soft spots in my floorboards throughout my custom renovated home. The top layer of teak flooring is in great shape. Can I somehow inject the liquid hardener into the soft spots to fix the rotted boards below?

Anthony Smiley –

I use the Wood sealer 1st . Then I used the wood filler. Both products were easy to work with. I was repairing a rotted 2 by 12 joist. The wood sealer made the would extremely hard again. I then use the would filler to fill in the large Spaces. The A and B wood filler was like playing with clay . Very easy to use. I will give it a five star after I sand and shape the wood. Ps I have pictures if you would like to see them. Let me know.

Laurel –

none better!

eugene weddle –

good

James Listman –

This stuff is a mandatory for anyone with an older home trying to maintain old sills etc. Making sure the old wood is dry is critical. It sucks right in and truly does make the original better!